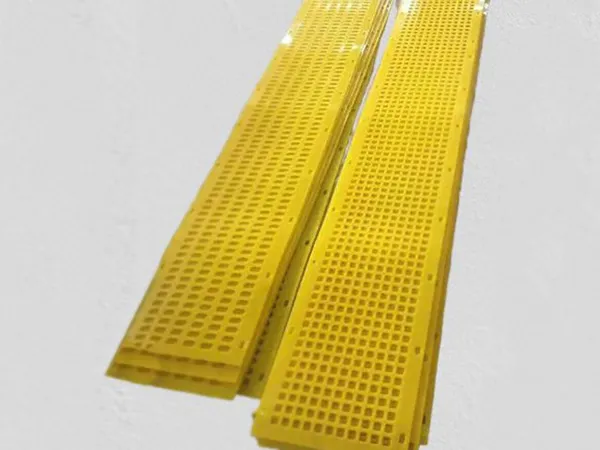

Polyweb polyurethane screen panels are specialized screen media typically used in vibrating screens for screening and classification of various materials in industries such as mining, aggregate processing, recycling, and construction. These panels are constructed from high-quality polyurethane material and offer several advantages over traditional steel wire or rubber screen media.

Polyweb Polyurethane Screen Panels Overview

Polyurethane Material: Polyweb screen panels are made from polyurethane, a durable synthetic material known for its resilience, abrasion resistance, and elasticity. This material provides excellent wear resistance and durability, resulting in longer screen panel life compared to traditional materials.

Modular Design: Polyweb screen panels often feature a modular design, with individual panels easily interchangeable and replaceable. This modular construction allows for quick and simple installation, maintenance, and replacement, reducing downtime and labor costs.

High Screening Efficiency: Polyweb polyurethane screen panels are designed to provide high screening efficiency and throughput. The panels feature unique apertures and designs tailored to specific application requirements, ensuring accurate and efficient material separation and classification.

Self-Cleaning: The flexible nature of polyurethane allows Polyweb screen panels to flex and vibrate during operation, preventing blinding and pegging of the screen openings. This self-cleaning action helps maintain consistent screening performance, even when screening sticky or wet materials.

Noise Reduction: Polyurethane screen panels offer noise reduction benefits compared to traditional steel wire screens. The flexible and damping properties of polyurethane help absorb vibration and reduce noise levels, creating a quieter working environment.

Corrosion Resistance: Polyurethane is resistant to corrosion, rust, and degradation from chemicals and environmental factors. This makes Polyweb screen panels suitable for use in harsh operating conditions and wet environments without compromising performance or longevity.

Customization Options: Manufacturers offer customization options for Polyweb screen panels, allowing customers to choose panel sizes, apertures, and configurations that best suit their specific application requirements. This customization ensures optimal screening performance and efficiency.

Polyurethane screens and sieve plates are widely used in screening machines for metallurgy, mining, building materials, water conservancy, road construction, coal mines, metal and non-metal mines. Steel wire and steel plate are used in the screen as the reinforcing skeleton. In addition, the polyurethane itself has a very high elastic modulus, high strength to absorb impact force and high wear resistance, so it has high tensile strength. Its bearing capacity is the same as that of the rubber screen. 2.5 times or more.

Its service life is 8-10 times longer than that of ordinary metal screens, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. It is currently the screen material with the best wear resistance in the world. The production material of polyurethane screen mesh is a macromolecule organic elastomer, which has excellent abrasion resistance, flex resistance and large bearing capacity. High screening efficiency, self-cleaning performance inside the screen surface, no hole blocking, high screening efficiency.

According to the actual measurement, the same screen machine using polyurethane screen can reduce noise by 5-20 decibels than metal screen, and greatly reduce dust flying. Although the price of polyurethane rubber screen is higher than that of metal screen, if factors such as screening efficiency, maintenance cost and service life are comprehensively considered, it will be found that the overall benefit of polyurethane screen is much better than that of ordinary metal screen.

According to the survey, every ton of polyurethane rubber screen plate can save 45 tons of steel. Save more than 40,000 yuan in maintenance costs. Therefore, replacing the steel screen surface with the polyurethane screen surface will be the inevitable choice for most enterprises in the future!

Polyurethane products have the properties of wear resistance, oil resistance, acid and alkali resistance, ozone resistance, aging resistance, low temperature resistance, tear resistance, impact resistance, high elasticity, strong vibration absorption, large load support capacity, etc. Machinery, construction machinery, chemical machinery, textile machinery, wood processing, printing machinery, metallurgical manufacturing, agricultural machinery and sports equipment and other industries.

Flip flop screening panels are polyurethane elastomers that are formed by a casting machine at one time. The structural design of this polyurethane screen shows the characteristics of good abrasion resistance, good elasticity, high elongation at break and resistance to bending of the polyurethane elastomer.

READ MORE

The composite screen mainly solves the problems of low strength and short service life of ordinary woven mesh. It consists of surfing the Internet and supporting the Internet. It has high strength, rigidity and carrying capacity, and can effectively reduce vibration noise and increase the service life of the screen.

READ MORE

The high accelerations caused by the stretching of the screen pads and excessive expansion of the openings of the Trisomat vibrating screen deck result in virtually no clogging of the screen. Our experts will assist you in selecting the best screen materials and fixtures for your feed.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.