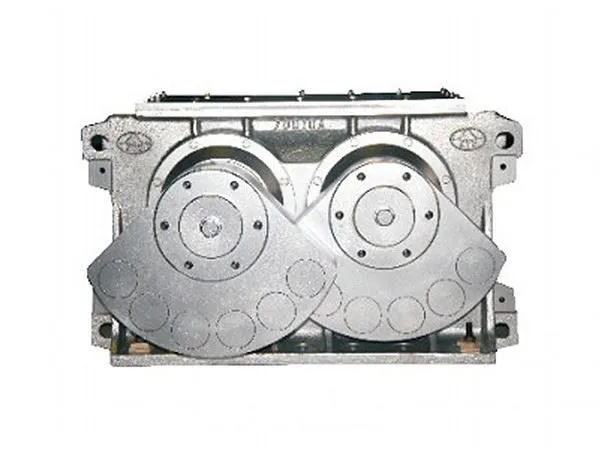

ZDQ series vibrators are versatile and reliable components used in a wide range of industrial applications to generate controlled vibrations for material handling, processing, compaction, and testing purposes. Their robust construction, high efficiency, and adjustable settings make them suitable for various industries requiring vibration-based solutions.

Technical Parameters

| Model | ZDQ30A | ZDQ20A | ZDQ20AF | ZDQ20AS | ZDQ10A | ZDQ09A | |

| Speed (r/min) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | |

| Static Moment | 1056 | 1687 | 1916 | 2092 | 2864 | 3596 | |

| (Kg•cm) | 1753 | 2906 | 3302 | 3600 | 4962 | 6096 | |

| Maximum Exciting Force (kN) | 395 | 319 | 362 | 395 | 545 | 603 | |

| Weight | 480 | 805 | 850 | 890 | 1260 | 1567 | |

| (Without Shield) | |||||||

|

Size(mm) |

A | 4×120 | 5×120 | 5×120 | 5×120 | 4×120 | 4×120 |

| A1 |

|

|

|

|

150 | 150 | |

| B | 260 | 300 | 300 | 300 | 390 | 390 | |

| C | φ25 | φ31 | φ31 | φ31 | φ31 | φ31 | |

| D | 35 | 25 | 25 | 25 | 40 | 40 | |

| E | 600 | 730 | 730 | 730 | 910 | 910 | |

| F | 750 | 830 | 830 | 830 | 1040 | 1135 | |

| G | 340 | 380 | 380 | 380 | 470 | 470 | |

| H | 663 | 861 | 907 | 961 | 984 | 997 | |

| I | 575 | 582 | 582 | 582 | 635 | 713 | |

| J | 320 | 325 | 325 | 325 | 380 | 395 | |

| K | 277 | 302 | 302 | 302 | 377 | 421 | |

Robust Construction: ZDQ series vibrators are typically built with durable materials and heavy-duty components to withstand the demanding conditions of industrial environments.

High Efficiency: These vibrators are engineered for optimal energy efficiency, providing reliable performance while minimizing power consumption.

Adjustable Settings: ZDQ series vibrators often come with adjustable settings for vibration intensity, frequency, and amplitude, allowing operators to customize the vibrations based on specific application requirements.

Low Maintenance: With sealed construction and few moving parts, ZDQ series vibrators require minimal maintenance, resulting in reduced downtime and lower operating costs.

Versatility: They are suitable for a wide range of applications across industries such as mining, aggregates, construction, recycling, food processing, pharmaceuticals, and more.

Working Principles

Electric Excitation: ZDQ series vibrators operate based on electromagnetic excitation principles. When an electric current flows through the vibrator coils, it generates a magnetic field that interacts with the armature, causing it to move back and forth.

Eccentric Weight: Each vibrator in the ZDQ series is equipped with an eccentric weight mounted on the armature. As the armature moves back and forth, the eccentric weight generates centrifugal force, leading to vibration.

Vibration Generation: The vibration produced by the eccentric weight is transmitted to the equipment or machinery connected to the vibrator, causing it to vibrate. This vibration facilitates various processes such as material handling, screening, compacting, and conveying.

Control: ZDQ series vibrators can be controlled manually or through automated systems such as variable frequency drives (VFDs) or programmable logic controllers (PLCs), offering precise control over vibration characteristics.

Applications

Material Handling: ZDQ series Vibrators are commonly used in material handling equipment such as vibrating screens, feeders, and conveyors to facilitate the transportation, sorting, and processing of bulk materials.

Screening and Sizing: They find applications in vibrating sieves and screens for separating particles based on size, shape, or density in industries such as pharmaceuticals, chemicals, and food processing.

Compaction: ZDQ series vibrators are utilized in compactors and vibratory compacting equipment to densify soil, asphalt, concrete, and other materials in construction, road building, and landscaping projects.

Foundry and Metalworking: These vibrators are used in foundry shakeouts and metalworking equipment to remove sand, debris, and burrs from castings, forgings, and machined parts.

Testing and Calibration: They are employed in testing equipment, instruments, and calibration devices that require controlled vibrations for performance testing, analysis, and quality assurance purposes.

The DF Series Vibrator refers to a range of specialized vibrators used in various industrial applications to generate controlled vibrations. These vibrators are designed for reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

NE Series Vibrators are versatile and reliable components used in a wide range of industrial applications to generate controlled vibrations for material handling, processing, compaction, and testing purposes. Their robust construction, high efficiency, and adjustable settings make them suitable for various industries requiring vibration-based solutions.

READ MORE

The FE series vibrator is a specialized component used in various industrial applications to generate controlled vibrations. These vibrators are designed to be reliable, durable, and efficient, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.