time:Apr 19, 2024 source:ZEXCIT

Motor vibration refers to the mechanical oscillations generated by an electric motor during operation. These vibrations are caused by various factors, including the rotating components of the motor, imbalance, misalignment, mechanical wear, and resonance within the motor and surrounding structures.

Rotating Components: Electric motors consist of rotating components such as the rotor (armature) and the stator. When the motor is powered, these components rotate at high speeds, generating centrifugal forces.

Imbalance: Imbalance occurs when the mass distribution of the rotating components is not uniform. Even minor imbalances can lead to significant vibrations. Imbalance may result from manufacturing variations, wear and tear, or improper installation.

Misalignment: Misalignment between the motor shaft and connected equipment, such as pumps or fans, can cause vibration. Misalignment can occur due to poor installation, thermal expansion, or mechanical stress.

Mechanical Wear: Wear and tear on motor bearings, shafts, and other components can lead to increased friction and vibration. Over time, components may degrade, leading to increased vibration levels and reduced motor efficiency.

Resonance: Resonance occurs when the natural frequency of the motor or connected equipment matches the frequency of external forces or vibrations. Resonance can amplify vibrations, leading to excessive wear and potentially damaging the motor and surrounding structures.

External Forces: External factors such as unbalanced loads, mechanical shocks, or environmental conditions (e.g., temperature fluctuations) can also contribute to motor vibration. These factors can affect the stability and performance of the motor system.

To mitigate motor vibration and ensure smooth operation, it's essential to address the root causes through various measures:

Balancing: Balancing the rotating components of the motor can reduce imbalance and minimize vibration. This may involve precision machining, adding balance weights, or dynamic balancing techniques.

Alignment: Proper alignment between the motor shaft and connected equipment is crucial for minimizing vibration. Laser alignment tools and precision alignment procedures can help ensure accurate alignment.

Maintenance: Regular maintenance, including lubrication, inspection, and replacement of worn components, can prevent excessive wear and vibration. Maintenance schedules should be followed to keep the motor in optimal condition.

Vibration Analysis: Monitoring motor vibration using vibration analysis tools can help identify potential issues early and take corrective action before they escalate. Vibration analysis techniques may include vibration sensors, accelerometers, and spectrum analysis.

By addressing the factors contributing to motor vibration and implementing appropriate measures, operators can minimize vibration levels, improve motor performance, and prolong the service life of electric motors and associated equipment.

MVT series vibrator compared with ordinary vibrators, MVT series vibrators have wider vibration coverage and more convenient installation. MVT series vibrators are widely used in coal, mining, petroleum, foundry, food processing and other industries. Used on vibrating screens, feeders and other equipment.

READ MORE

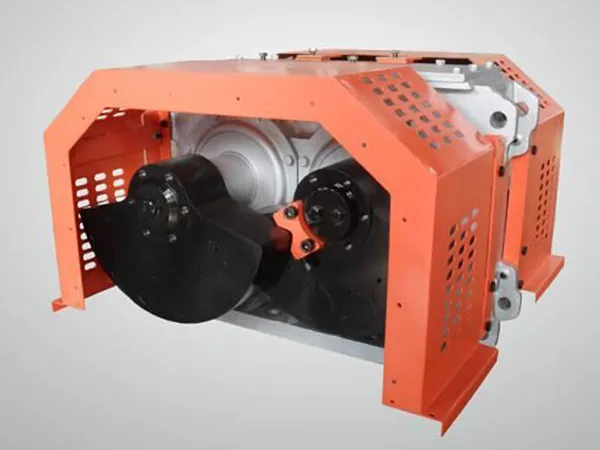

The VBH series vibration motors are specialized electric motors designed for generating controlled vibrations in various industrial applications. These motors are known for their reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

VB series vibration motors are used as the excitation source of various types of vibration machinery, such as vibrating feeders, vibrating conveyors, vibrating ore discharge machines, vibrating sand shakers, vibrating screens, and vibration anti-blocking devices for silos, etc., and are widely used Electricity, building materials, coal, mining, metallurgy, chemical industry, light industry, casting and other industries.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.