time:Apr 28, 2025 source:ZEXCIT

To extend the service life of your vibrating screen and ensure efficient operation, a consistent and thorough maintenance program is essential.

Frequency: Daily, weekly, and monthly inspections are crucial.

What to check:

Screen Media: Look for tears, holes, wear, proper tension, and cleanliness. Ensure it's correctly installed and that gaskets (if required) are in place.

Structural Components: Examine the frame, supports, and cross beams for cracks, fatigue, or damage.

Fasteners: Regularly check and tighten all bolts, nuts, and other fasteners, especially on screen panels, clamping systems, and motor mounts. Re-tighten bolts after the initial 7 hours of work.

Springs: Inspect for wear, damage, and proper compression. Measure springs against OEM tolerances and replace as a complete set if out of tolerance.

Crown Bars: Ensure proper and continuous crown on all decks. Repair or replace according to the manufacturer's guidelines.

Drive System: Inspect V-belts for wear, damage, and proper tension. Check for leaks in the drive system.

Mounting System: Ensure the machine is securely mounted and free from damage.

Safety Guards: Confirm they are firmly in place and not compromised.

Why: Early detection of issues prevents more significant damage and downtime.

Frequency: Follow the manufacturer's recommendations for lubrication intervals. Daily lubrication of drive bearings and ensuring grease lines are intact is often necessary.

What to do:

Lubricate bearings, drive mechanisms, and other moving parts with the recommended lubricant and quantities.

Inspect grease lines for leaks or blockages.

For central lubrication systems, perform thorough inspections weekly.

Monitor bearing temperature; overheating can indicate lubrication issues.

Why: Reduces friction and wear, preventing premature failure of moving parts.

Frequency: Clean the screen surface regularly, the frequency depends on the material being screened. Daily cleaning is often necessary.

How to do it: Use a brush, air blower, or water spray (depending on the material and screen media) to remove buildup of material, debris, or blockages.

Why: Maintains efficient screening performance and prevents excess weight and strain on the screen.

What to do: Replace worn or damaged screen media, bearings, drive belts, seals, and springs promptly.

Why: Prevents inefficient screening, increased vibrations, further damage to the equipment, and potential failures. Using genuine parts from the manufacturer is recommended.

Startup and Shutdown: Start the screen without load and feed material only after it runs smoothly. Before shutdown, stop feeding and allow material on the screen to be discharged.

Feeding: Feed material evenly across the full width of the screen, as close to the feed end as possible. Avoid excessive material thickness on the screen. The maximum drop height from the feed point to the screen surface should ideally be no more than 450mm to minimize impact.

Avoid Overloading: Do not exceed the designed capacity of the vibrating screen.

Operator Training: Ensure all operators are properly trained on safe and efficient operation.

Why: Proper operation minimizes unnecessary wear and tear and ensures optimal screening efficiency.

What to do: Ensure the vibrating screen is installed correctly on a stable foundation. Regularly check for excessive vibration or noise, which could indicate imbalance or loose parts.

Why: Reduces stress on the structural components and extends the life of the equipment.

What to do: Select screen media (wire mesh, polyurethane panels, rubber, or non-metallic screens) that are suitable for the material being screened and the application. Non-metallic screens can offer better wear resistance and reduce noise in some applications.

Why: Using the correct screen media can significantly improve screening efficiency and extend its service life.

By implementing these maintenance practices, you can significantly extend the service life of your vibrating screen, reduce downtime, and maintain efficient screening operations. Remember to always consult the manufacturer's manual for specific maintenance recommendations for your equipment.

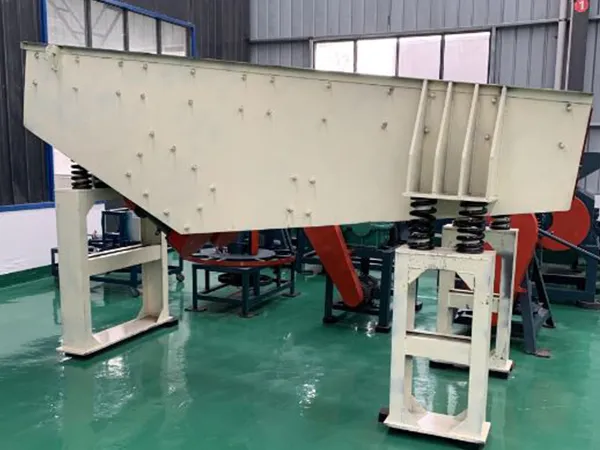

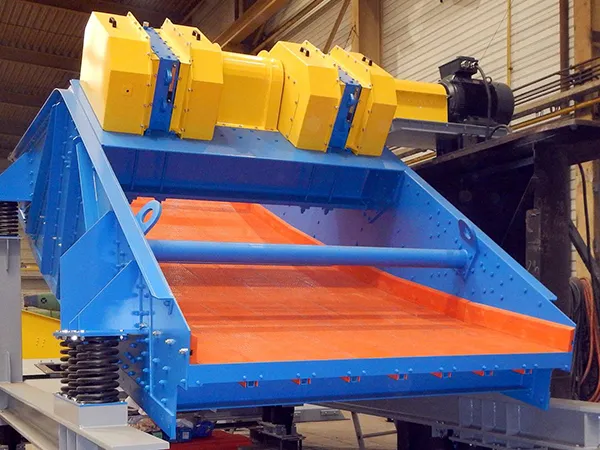

ZSK eccentrics series linear vibrating screen is a new and efficient universal screening equipment, screen box trajectory which is approximately a straight line. This series of screen machine embodies most of the advantages of a biaxial linear screen, with the most extensive scope and application prospects.

READ MORE

The DF Series Vibrator refers to a range of specialized vibrators used in various industrial applications to generate controlled vibrations. These vibrators are designed for reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

A flip flop vibrating screen is a type of vibrating screen that utilizes the principle of elasticity to effectively screen and separate fine materials. This unique design creates a flip-flop motion during the screening process, which helps prevent material blinding and pegging.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.